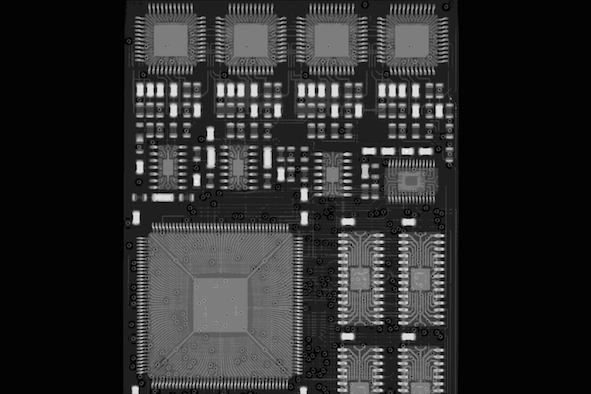

Digital X-ray radiography allows quick examination of components and is therefore frequently used for quality control in the production process. Hereby, electronic components can be tested for faulty contacts or cable breaks, for instance. A three-dimensional display of the object, however, is not possible with this method.

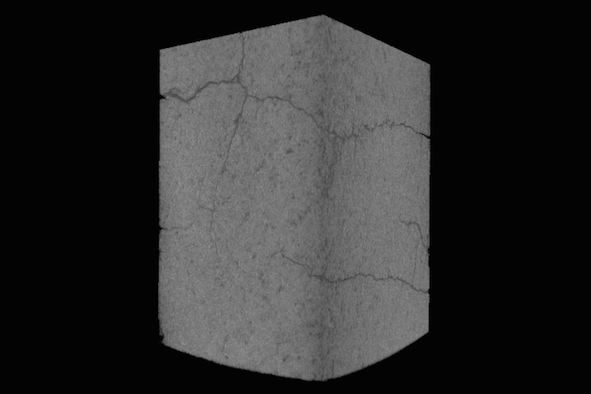

In micro computed tomography X-rays pass through an object from different angles with the aqcuired data allowing the reconstruction of a three-dimensional computer model. This makes it possible to visualize or quantitatively evaluate the distribution of porosities in rock samples, such as concrete, for example.

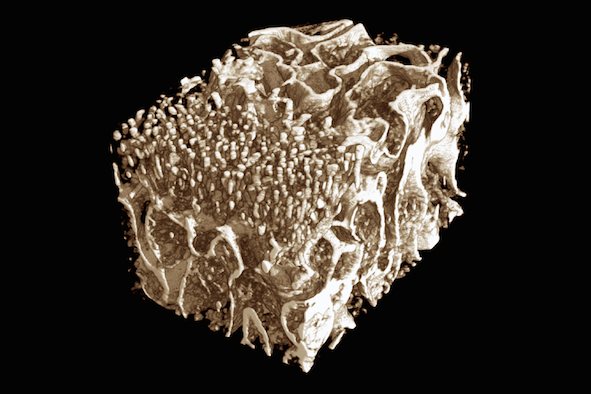

With micro computed tomography structures with a size of 5 to 10 µm or more can be displayed which, for example, allows the examination of trabecular bone architecture. Thus, medical technology is in the position to study the reconstruction of bone material or to gain information for the modeling of bone elasticity and capacity.

Micro computed tomography is a non-destructive examination method and therefore the number one choice when it comes to analysing valuable and unique objects such as works of art or ancient artefacts.

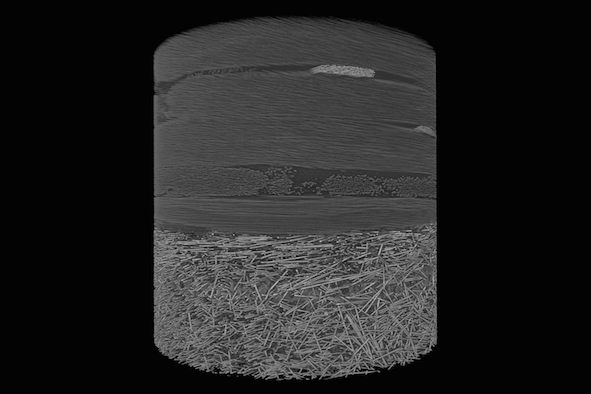

Submicro computed tomography enables three-dimensional insights into objects with resolutions of one micrometer and less. That way the individual fibers of fiber reinforced plastics can be visualised and analysed.

With submicro computed tomography one can visualize extremely small fissures and minimal porosities. That way, quality in various manufacturing processes can be controlled or materials tested for heat resistance.

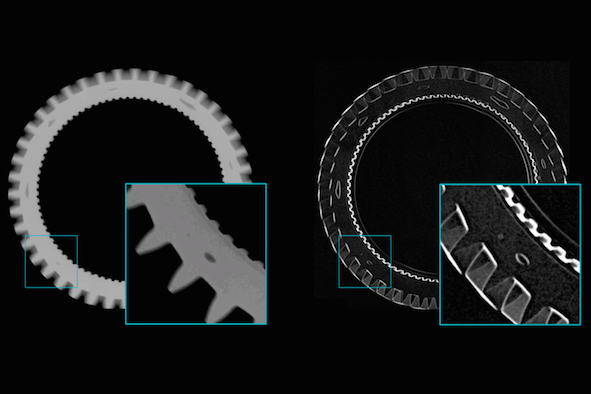

Digital radiography is often used to detect air pockets in injection-molded parts. The smaller the airpockets, the more easily they can be overlooked during examination. By means of dark-field radiography reliability could significantly be increased, here.

The use of carbon fiber reinforced components in aviation and the automotive industry is constantly increasing. X-ray dark-field imaging is a recently developed, highly promising method for examining CFK and CFRP structures and detecting and characterizing impact and hail damage. It can thus be used in future for quality assurance of fiber reinforced components.

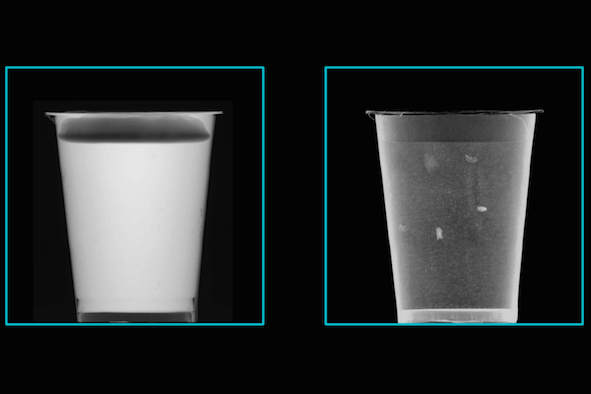

Dark-field imaging is sensitive to structures which are below the actual resolution limit of the X-ray system used. This makes it possible to safely identify fine details in larger objects such as foreign bodies in yoghurt.

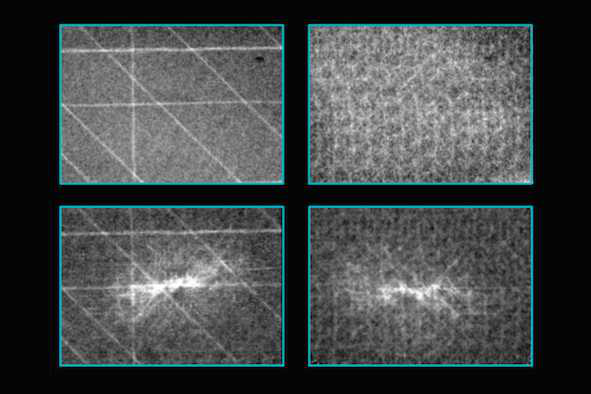

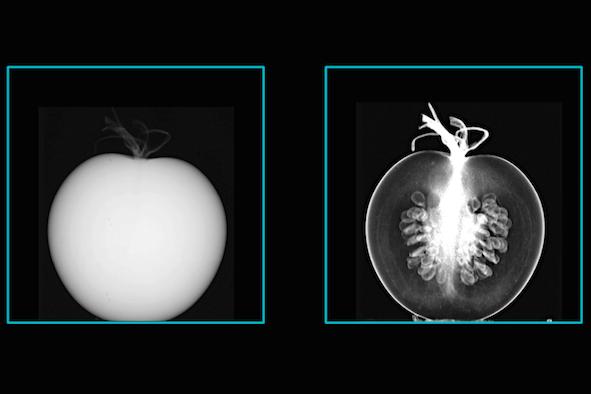

If the inner structures of an object in digital radiography do not create sufficient contrast, dark-field imaging may be a promising alternative. In this example, the seeds and transportation routes inside a tomato, which are not displayed in regular radiography, can be made visible by X-ray dark-field radiography.

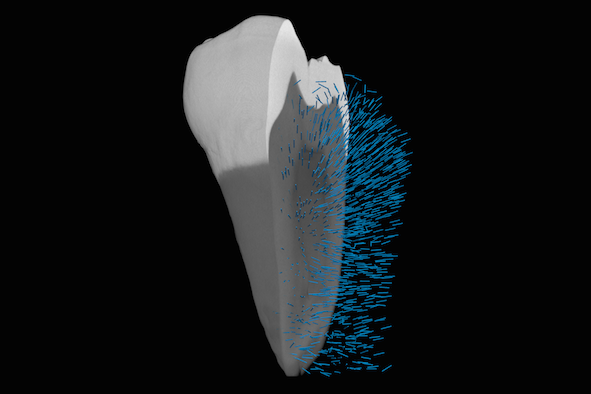

Tensor tomography is the three-dimensional extension of dark-field radiography. It allows the characterization of structures below the actual detector resolution. As compared to regular micro computed tomography even the orientation of extremely fine canals in a tooth can be displayed that way.

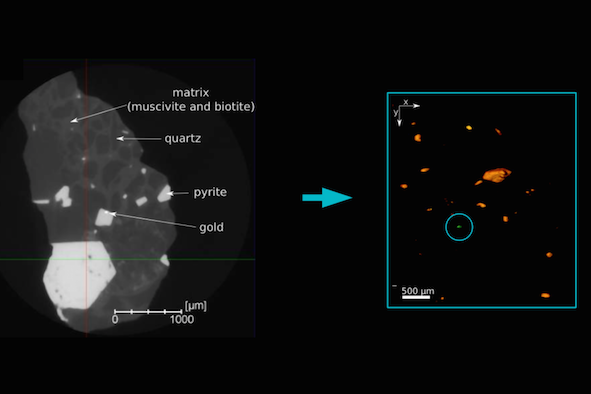

With multi-energy procedures one can characterize the different metals in an object more precisely and distinguish them from one other. Hereby, - as is the case in the gold ore sample shown here - the gold particles can be differentiated more clearly from other materials such as lead.

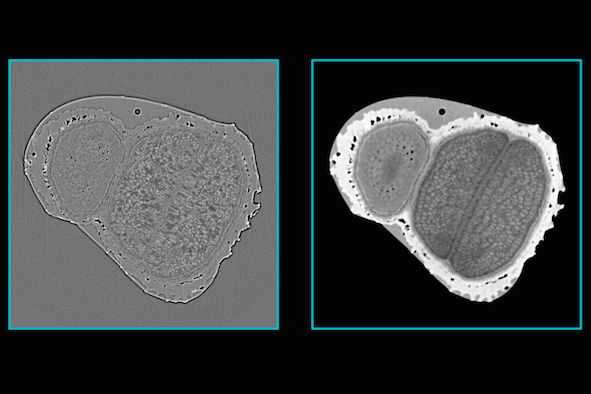

Sometimes the necessary contrast between individual structures can not be achieved due to the low absorption of X-rays. In this case, high-resolution submicro computed tomography scans allow the extraction of phase-contrast images, which are richer in contrast.

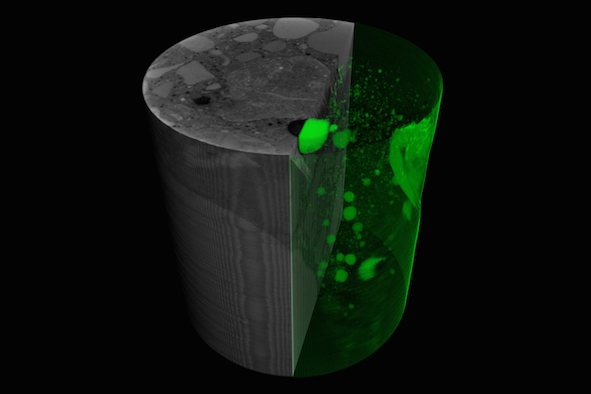

In biological tissue samples a significant increase in contrast is possible through the application of suitable contrast agents. If the sample is prepared accordingly before measuring, this method allows for example the visualization of tumors.

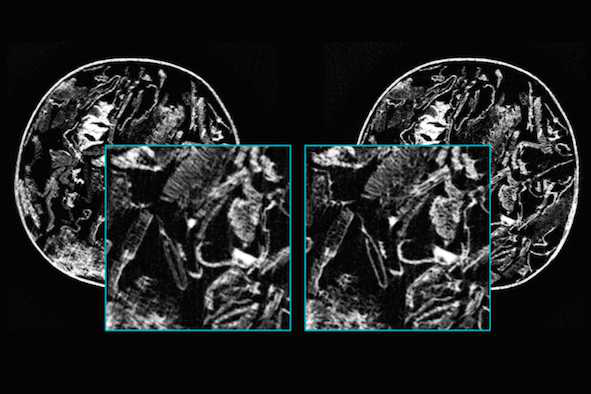

In tomographic examinations with very high resolutions minimal motions of the sample can cause fine details in the reconstructed image to be blurred. If advanced algorithms for data processing are applied, such artefacts can later be corrected making a repeated measurement unnecessary.