We have access to a large variety of conventional and novel X-ray imaging technologies to obtain the best possible imaging result and extract a maximum of information on your sample for answering your specific questions.

Digital X-ray radiography (radiographic examination) is used to get a first impression of the inside of an object or to carry out a quick test of components. To that purpose, the object is irradiated by X-rays and a magnified 2D shadow image is produced with the help of an X-ray detector.

This relatively simple X-ray modality makes it possible to detect different defects as voids, cracks or broken cables. Since a 3D object is reduced to a 2D image by this method, inner structures may overlap and conceal each other.

In CT imaging hundreds or thousands of X-ray images are recorded during a 360 degree rotation of an object. A detailed 3D model is then computed from the acquired data. The digital representation of the object allows for reliable identification, accurate localization and versatile analysis of internal features and structures.

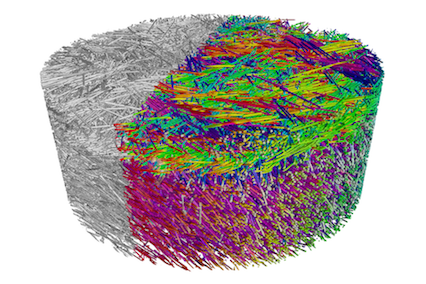

The term micro CT is used, when the sample is measured and presented with a spatial resolution of about 5 µm up to some 100 µm. Small microstructures like fibers can be made visible with the help of submicro CT, which can realize resolutions ranging from 5 µm to below 1 µm. The achievable resolution usually depends on the object size and the specific task.

The precise three-dimensional digital respresentation of an object that is obtained by computed tomography enables great opportunities for further data analysis and the extraction of various quantitative object parameters. We use powerful software tools for the processing and analysis of CT data to get a maximum of information on your object:

The manifold developments and rapid progess in the area of X-ray imaging create enormous potential for new kinds of inspection tasks in all industries.

If conventional X-ray modalities reach their limits, we have profound knowledge and the possibilities to evaluate latest technologies due to our close contact to the Institute of X-ray physics at the TU Munich and our far-reaching academic network. That way, current developments in research become immediately available to our customers.

Our expertise includes the following techniques:

A more detailed description can be found here.

X-ray imaging is a contact-free non-destructive testing method.

X-ray imaging enables to inspect your object's inner structures.

X-ray imaging provides 3D geometric information for your entire object.

X-ray imaging achieves resolutions down to below one micrometer.

X-ray imaging delivers a numerous of characteristics for your object.

X-ray imaging is applicable for nearly all kind of objects and materials.

The precise non-destructive examination of objects and their inner structures with X-ray micro computed tomography enables great perspectives for failure analysis, quality control, material characterization and process optimization.

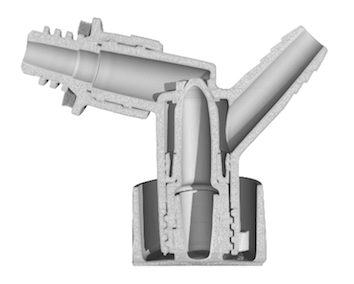

Casting part | Resolution: 100 µm

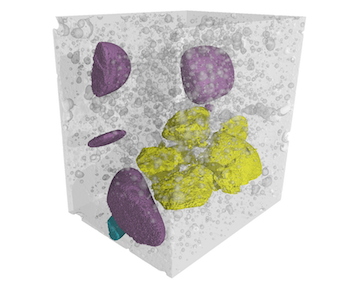

Plastic component | Resolution: 110 µm

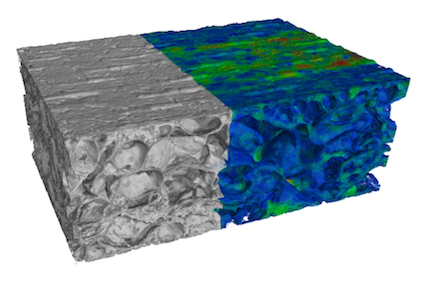

Concrete sample | Resolution: 70 µm

Aluminum foam | Resolution: 20 µm

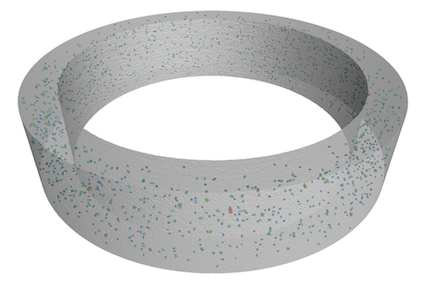

Ceramic ring | Resolution: 3.2 µm

Carbon fiber composite | Resolution: 1.8 µm

Our experienced team supports you from the initital question to the final answers. We develop a plan of action, perform the scans, analyze the data and prepare the results for your best understanding.